Heavy Duty Oil Trucks Need Heavy Duty Parts

Learn Why The Petroleum Industry Prefers Moro Pumps

Industrial trucks transporting and transferring various petroleum products rely extensively on heavy-duty pumping systems. These systems employ vacuum pumps, storage tanks, valves, and pipes for moving liquids between storage containers, process equipment, and truck reservoirs efficiently and safely.

Therefore, equipping the trucks with high-quality pumping accessories enhances functionality while the right maintenance tools ensure longevity through scheduled care. Powerful vacuum pumps enable quick suction and transfer of oil and petrochemical products with varying viscosities.

Some of the most vital categories of pump supplies for gas and oil tanker trucks are discussed in the run down below.

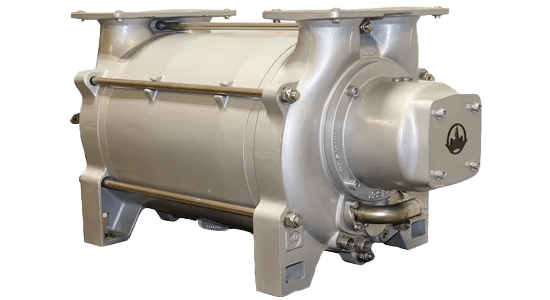

Moro PM80T Vacuum Pump

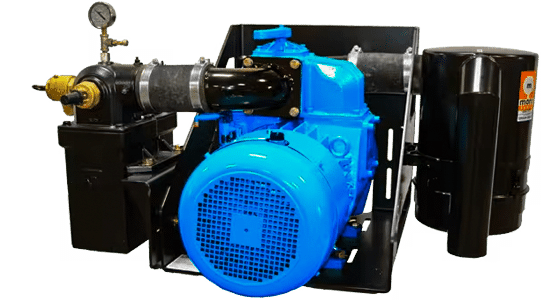

The rugged Moro PM80T Vacuum Pump rotary vane vacuum pump leverages a dual vertical cooling fan arrangement that keeps the large iron casing cooler for continuous duty across challenging industrial applications. Onboard accessories like the check valve and dedicated oiling system simplify installs.

Moro PM80T Benefits

At modest speeds below 1500 RPM, the slotted carbon vanes, Viton shaft seals, and integrated sight glasses demonstrate exceptional vacuum sealing to 29″ Hg across 3″ ports. This heavy-duty air-cooled pump handles filthy suction transport reliably without relying on external cooling lines that risk engine heat soaking. Superior construction ensures sustained performance longevity when deployed relentlessly across remote waste transfer sites.

The pumps need to overcome high static heads for stripping storage tanks entirely. Noise mufflers reduce emissions. Choose pumps that match the required flow rates and maximum achievable vacuum levels for the application. Ensuring optimal performance in pump supplies for gas & oil industrial trucks involves selecting the right equipment to meet the demands of frequent, heavy-duty use.

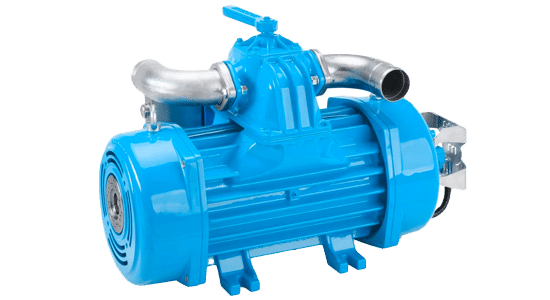

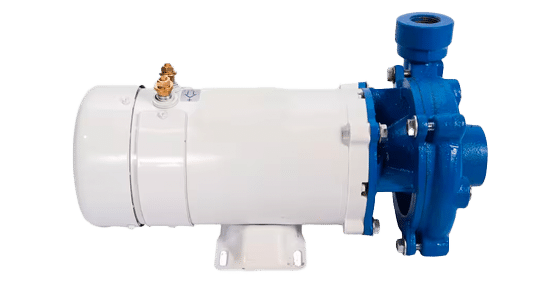

MORO PM110W Vacuum Pump

The Moro PM110W Water Series Vacuum Pump is engineered to be one of the top vacuum pumps for heavy-duty gas and oil trucks. It utilizes high-performance Kevlar vanes that provide strength and durability. Convenient visual inspection ports in the casing allow technicians to monitor the vanes. It also features high-quality Viton oil seals that offer an extended service life compared to old-fashioned seals, resulting in fewer leaks as the pump ages.

Moro PM110W Benefits

In addition, the PM110W has a low rotational speed that puts less strain on components, leading to prolonged pump life. Oiled bearings ensure smooth operation even under heavy loads. The direct feed and the sealed oiling system maintain steady lubrication, while the remote oil tank keeps oil away from the pumping chamber. Technicians appreciate the quiet operation of the PM110W. It can work unobtrusively at night near neighborhoods.

Our pump is configured for 3″ or 4″ hose connections for integration with different oil trucks. Its hardy construction and optimized design focused on reliability, the Moro PM110W delivers lasting performance and minimal downtime. This makes it a premier vacuum pump option for gas and oil industrial vehicles. Moreover, the Kevlar vanes, Viton seals, and low-speed operation allow it to withstand demanding field conditions.

Kaiser 900i Liquid Ring Vacuum Pump

The Kaiser 900i Liquid Ring Vacuum Pump is engineered to be one of the top liquid ring vacuum pumps for heavy-duty gas and oil trucks. It features a lightweight aluminum construction that keeps overall weight low. The 900i utilizes permanently lubricated bearings that require minimal maintenance. It offers flexible drive options, including a V-belt, coupling, or hydraulic motor to match different truck configurations.

Kaiser 900i Benefits

A vital advantage of the 900i is its environment-friendly operation. Since it uses water as the sealing liquid instead of oil, the discharge line has no oil emissions. This makes it a greener vacuum solution. Furthermore, technicians will also appreciate the extremely quiet operation of the 900i. It can work unobtrusively with minimal noise disruption.

Essential Accessories & Supplies for Petroleum Trucks

Alongside suitable vacuum pumps, carrying essential accessories and supplies in the gas industry’s work vehicles ensures smooth day-to-day functionality. Some vital items include:

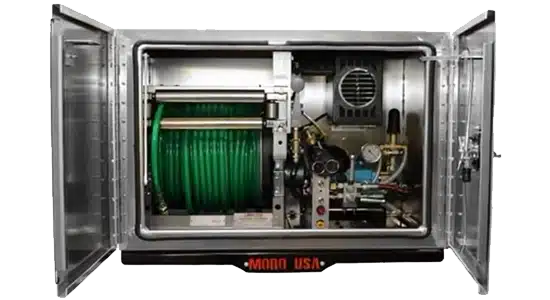

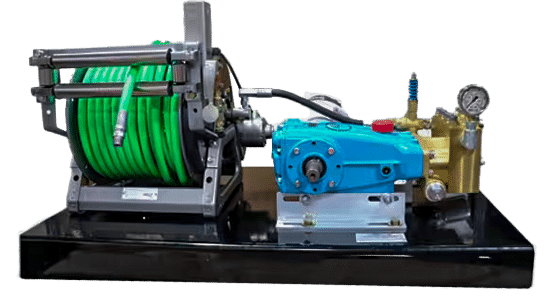

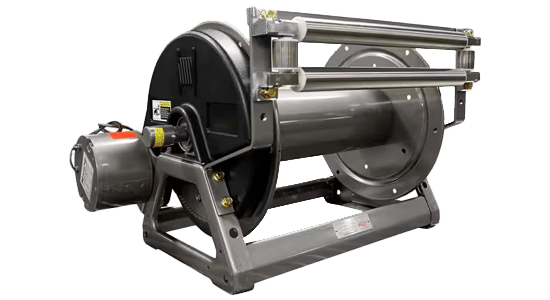

Gas Truck Hose Reels

Vehicle-mounted hose reels such as Hannay Reels® Jetter Hose Reel For 1″ Hose provide kink-resistant storage and smooth payout of lengthy discharge and suction hoses for material transfer to/from distant points. Key factors include:

Hose Capacity: The drum fitting length varies from 100 ft for a small, enclosed reel to 600 ft for large open models, allowing extended reach without shifting the vehicle. Consider hose bore, wall thickness, and fluid when sizing reel capacity.

Drive Type: Reels use manual or motorized drives to retrieve heavy hoses effortlessly. Brakes prevent freewheeling. Consider speed control for avoiding hose whiplash upon full retraction.

Mounting: Standard rear bumper-mounted reels provide stability, offering 270° swing for flexibility. Reels carrying thick, large-diameter hoses may require reinforced floor mounts to support tremendous hose weights exceeding 1000 lb.

Well-designed hose reels simplify fluid transfer logistics for operators while enhancing site access. Moreover, look for versatile mounting, rugged drives, and generous capacities when selecting reels.

Pressure Gauges for Oil/Gas Trucks

The 2-1/2″ Liquid Filled Back Mount Pressure Gauge allows monitoring system discharge pressures up to 5000 PSI across industrial pumping systems and hydraulic drives. Its compact 1/4″ back mount design allows installing the gauge in space-constrained pump panels to check operational parameters at a glance. The gauge relies on an internal glycerin-filled bourdon tube sensing element that delivers smooth and dampened pressure readings compared to dry designs. This prevents needle fluctuations.

Plus, a 2 1⁄2″ dial face improves the visibility of the large glow-in-dark figures and markers, prominently indicating the 0-5000 PSI scale. The heavy-duty stainless-steel construction and blow-out rear safety plug ensure durability across vibrating pump environments with occasional pressure surges. Its versatility suits applications ranging from vacuum truck systems to high-pressure water jetters.

Nozzles and Valves

For controlled fluid loading/unloading, various valves and nozzles are installed in the pump system circuit. Examples include:

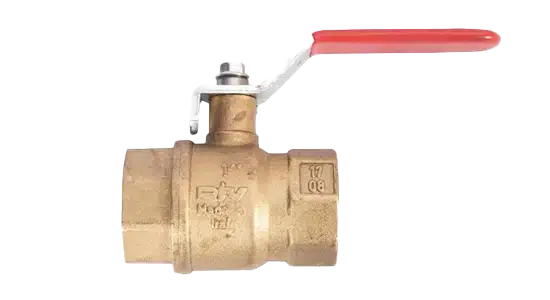

Ball Valves: Quarter-turn ball valves provide convenient shut-offs before disconnecting transfer hoses using mechanical friction. Reinforced PTFE seats suit both oil and gas.

Butterfly Valves: Lightweight butterfly valves suit corrosive services with stainless steel discs and EPDM seals. The compact integral design suits space constraints.

Nozzles: Automatic shut-off nozzles prevent spills upon tank filling. Variants allow fixed flow rate control for metering additive injections when reclaiming oil.

Choosing corrosion-resistant valves in larger diameters reduces pressure drops for high-viscosity products. Invest in quality nozzles for smooth fluid flow control during transfers.

Why Petroleum Professionals Choose Moro Pumps for their Trucks

The unpleasant nature of septic tank cleaning places heavy demands on the vacuum pumps and accessories used in septic service vehicles. Rugged air-cooled vane vacuum pumps offer small trucks an economical, reliable pumping solution. Large dual fan-cooled pumps generate a higher vacuum for increased productivity.

Liquid ring pumps provide a maintenance-friendly alternative to handle high moisture septic gasses. For extreme tropical duty cycles, liquid-cooled vacuum systems deliver operational safety. Alongside suitable pumps, carrying vital supplies improves field service responsiveness.