Best Pumps & Supplies For Septic Service Trucks

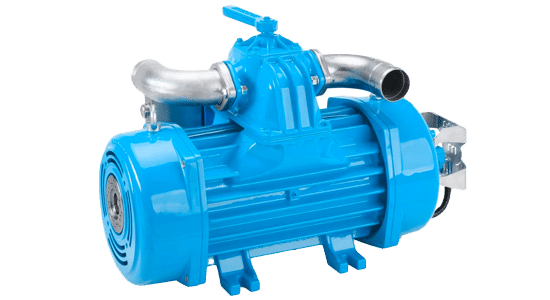

Learn Why Septic Servicemen Prefer Moro Pumps

Septic service trucks perform the critical task of cleaning and maintaining septic systems to ensure proper sewage disposal. This could be from homes and buildings lacking connections to main sewer lines. Moreover, to suck sewage and effectively convey various waste fluids, these trucks utilize heavy-duty vacuum pumps coupled with specialized containment tanks and accessories.

Selecting suitable vacuum pumps and the right accessories for your septic service truck is vital for the seamless daily operation of septic service vehicles across various locations.

Based on the mounting configuration, cooling methods, construction, and capability, some of the best vacuum pumps and vital supplies for septic trucks are discussed below:

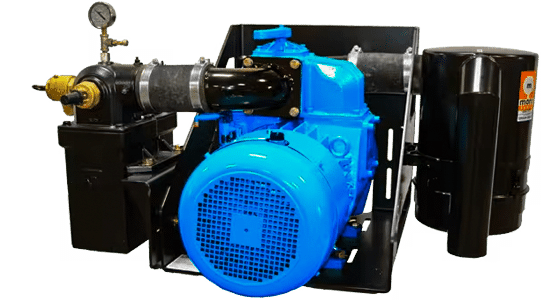

Moro PM60A Vacuum Pump

The Moro PM60A Vacuum Pump is an industrial rotary vane vacuum pump adopting several design refinements targeting noise reduction for urban waste transfer applications where sound emissions need containment. This starts with a large open-ported manifold to allow unrestricted air passage and minimal friction as vacant air pockets get compressed by the rotating vanes before discharge.

Moro PM60A Benefits

The four-vane rotor and end plates use proprietary Kevlar resin injected into a carbon fiber composite matrix shaped into precisely honed convex profiles. The lightweight Kevlar vanes demonstrate nearly 10 times the tensile strength of standard carbon vanes while retaining flexibility and resilience after repeated cycling. This averts tip damage when ingesting occasional solid debris across raw sewage or drilling waste streams. Additionally, unique inspection viewports machined on the casing provide a periodic peek to assess vane edge health without needing complete teardowns.

Also, the Viton shaft seals having composite PTFE elements demonstrate exceptional chemical and heat resistance. This allows cooler running over thousands of miles compared to standard seals. The latter displays a progressive hardening and cracking tendency when exposed to hot contaminated carryover demands in waste haulage. Additionally, external sealed-for-life roller bearings require no routine lubrication, resulting in clean operation. These features make them indispensable components of septic/grease truck supply, ensuring reliable and efficient performance even in demanding waste management scenarios.

Moro PM70A Vacuum Pump

The Moro PM70A AIR Series Vacuum Pump leverages a large open intake manifold that enables smooth, quiet airflow ingress through minimized friction. Durable Kevlar vanes allow periodic visual checks through special casing viewports. The Kevlar composite demonstrates 10 times the tensile strength over traditional carbon, resisting tip damage from occasional debris. Superior Viton seals resist heat degradation for extended working life across contaminated streams.

Moro PM70A Benefits

With conservative operating speeds under 1300 RPM, external remote oil tanks, and sealed bearings reduce power losses, focusing on quieter vacuum delivery through 3″ ports. Thoughtful optimizations targeting noise reduction, minimal maintenance, and longevity address key pain points reported in vacuum truck applications involving urban waste transfer or strict environmental regulations.

The PM70A aims at reliable performance across thousands of hours in the field, making it an essential component of septic truck pumps for dependable waste management operations.

Moro PM80A Vacuum Pump

The Moro PM80A Vacuum Pump adopts a large open intake manifold that allows smooth, quiet airflow ingress to the compression chamber, minimizing friction and noise during pumping. The four-vane rotor utilizes high-strength Kevlar resin injected into a carbon fiber matrix for 10 times the tensile resilience versus carbon vanes. This allows periodic visual checks through unique casing viewports. Viton shaft seals last over 50% longer than standard seals due to higher heat resistance.

Moro PM80A Benefits

A remote oil tank prevents contamination, while optimized lobe profiles at conservative 1250 RPM shaft speeds focus on quieter operation. Sealed bearings require no routine lubrication for an extended lifetime.

These enhancements aim at reliable low-noise vacuum delivery for stringent urban applications. 3″ ports allow customizable access for waste haulage across truck configurations.

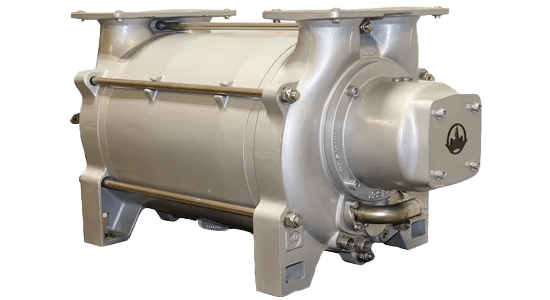

Moro PM70T Vacuum Pump

The Moro PM70T Vacuum Pump is explicitly engineered for rugged, heavy-duty applications, often involving continuous vacuum pumping across remote waste processing sites. It leverages a dual cooling fan design, with the fans symmetrically blowing air vertically upwards over both sides of the large cast iron pump casing. This prevents uneven cooling, ensuring reliable non-stop operation even under 100°F heat without risk of overheating failures that plague competitive pumps.

Moro PM70T Benefits

Unlike auxiliary liquid-cooled systems that eventually degrade the vehicle’s own radiator performance, the self-contained air-cooling arrangement requires no expensive plumbing. Technicians can simply replace standalone fans or thermostats when required. The on-board integrated accessories like check valve, changeover valve, and transparent oil sight glass further simplify installation without needing additional interfaces.

Central to the PM70T is exceptional sealing ability from high-grade Viton oil seals combined with precision ground hardened steel rotor and tough slotted carbon vanes that handle peak vacuum pressures of 29″ Hg across 3″ intake ports – at almost half the RPMs compared to conventional designs. This means lower friction enabling a long working life even across applications seeing contaminated carryover during drilling waste transfers.

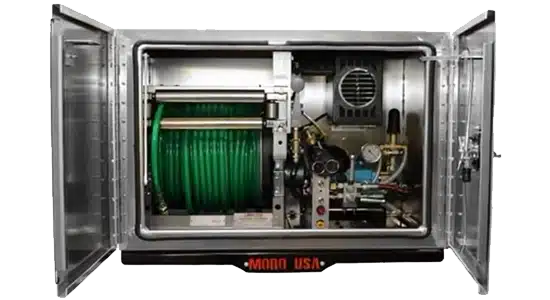

Essential Accessories & Supplies for Septic Service Trucks

Alongside suitable vacuum pumps, carrying essential accessories and supplies in septic service vehicles ensures smooth day-to-day functionality. Some vital items include:

Tru-Align Gearbox Bracket/Coupling Kit

The Tru-Align Gearbox Bracket/Coupling Kit allows the versatile mounting of Moro PM series pumps to existing gearboxes on vacuum trucks. It does this by correcting up to 3.5 degrees of angular misalignment using a rugged sway bracket. This prevents premature failure of powertrain U-joints from side loading forces.

By retaining precise axial shaft alignment despite chassis twists, the coupler set reduces stresses, vibration, and noise during prolonged transfers through uneven terrain. The sturdy bracket is designed to directly replace attachments of alternative vacuum pump models using adaptable mounting holes for trouble-free installations. These features make it an invaluable component for grease truck repair, providing efficient and quiet operation with minimal maintenance requirements.

3" Pressure/Vacuum Relief Tree Deluxe Kit

The 3″ relief tree kit features robust aluminum blocks specifically fabricated using quality domestic US castings to withstand powerful vacuum pumps on septic trucks. Considerably, the kit consolidates a gauging block, vacuum relief, pressure relief, and consumable flush reservoir into one chassis mount assembly for simplified field installations.

Notably, the 2.5″ stainless steel compound gauge preemptively monitors cycling pressures to enhance diagnostics.

Plus, the vacuum relief prevents implosions by rapidly exhausting up to 1.5″ tubes if negative inlet pressures approach CFM-dependent setpoints. To protect hoses and workers from catastrophic bursts during overpressure, a wide-flow 2″ pressure relief valve addresses the risk.

Why Septic Service Professionals Choose Moro Pumps for their Trucks

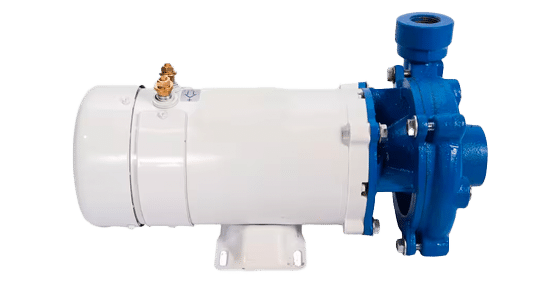

The unpleasant nature of septic tank cleaning places heavy demands on the vacuum pumps and accessories used in septic service vehicles. Rugged air-cooled vane vacuum pumps offer small trucks an economical, reliable pumping solution. Large dual fan-cooled pumps generate a higher vacuum for increased productivity.

Liquid ring pumps provide a maintenance-friendly alternative to handle high moisture septic gasses. For extreme tropical duty cycles, liquid-cooled vacuum systems deliver operational safety. Alongside suitable pumps, carrying vital supplies improves field service responsiveness.