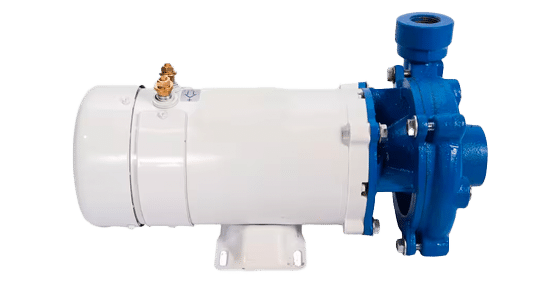

2″ RIV High-Capacity Pressure Relief Valve

- Adjustable, spring-loaded pressure Relief Valve

- Tamper-proof cap

- Corrosion-resistant brass body

- Zinc-plated steel springs and fasteners

- Extremely high temperature handling 0C/32F up to 180C/356F

- Convenient, environmentally compatible hose shank outlet

- Maximum pressure 7-21 PSI

- 2″ inlet

$52.00

Description

All RIV pressure relief valves are designed to alleviate additional pressure that may be created in your tanks due to changes in ambient temperature or other environmental factors. However, with higher capacity needs some larger systems require a relief valve that can handle more. This is more than double the ability of the typical relief valve of this size.

A type of safety valve, this 2-inch pressure relief valve is the most important safety feature for your vacuum truck – releasing extra pressure to avoid the worst-case-scenario of a tank exploding and hurting or killing someone.

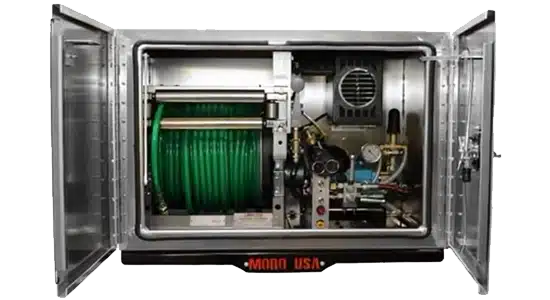

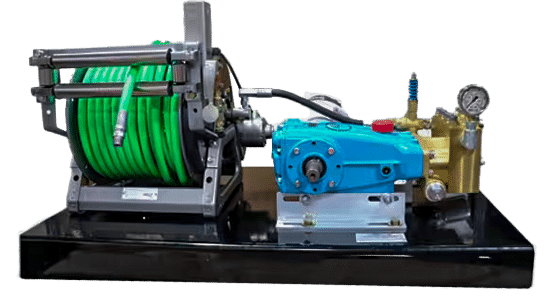

Pressure relief valves are generally positioned on your vacuum pump truck’s primary or secondary tank but can be retrofitted to go between the primary tank and the secondary scrubber. An adjustable pressure relief valve is often paired with a vacuum relief valve, and both can be monitored with a dual vacuum/pressure gauge as seen in Moro’s Pressure/Vacuum Relief Tree. A vacuum relief valve functions similarly to a pressure relief valve but is more concerned with keeping the vacuum pump safe and preventing tank implosion, rather than the larger issue of keeping personnel safe.

RIV relief valves are easily adjustable for routine maintenance and on-the-job pressure modifications.* Changing the pressure is as simple as loosening the lock nut, turning the spring-tightener clockwise to compress the spring (increasing the pressure) and counter-clockwise to release the spring (decreasing pressure), then tightening the lock nut to set. Adjustable safety relief valves are also designed with tamper-proof caps. These caps come with pre-drilled holes in tiny “tongues” with a ring inserted to prevent accidental pressure changes or to deter arbitrary tinkering of safety equipment.

*Pressure relief valve will need to be adjusted in the field for your unique truck/tank specifications and application. We recommend 5 PSI maximum tank pressure.

The RIV 2” High-Capacity Pressure Relief Valve also features a convenient hose shank connection to divert air and overflow liquids away from the vacuum pump to an appropriate vessel. This keeps your pump cleaner, reduces maintenance for you and your staff, and extends the overall life of the pump.

Constructed with a solid brass body and zinc-plated steel springs and fasteners, RIV pressure relief valves are manufactured using anti-corrosive materials to protect your valve from moisture. RIV valves also use gaskets constructed from FPM (Viton), a high-grade, versatile synthetic rubber known for its ability to perform well in high-pressure and high-temperature situations as well as its excellent resistance to weathering, oxidation, and chemicals such as oils and fatty acids. When safety is an issue, high-quality materials can make all the difference. Breathe a sigh of relief knowing you can depend on your RIV safety relief valve to keep you and your equipment safe for years to come.

How it Works

Under normal circumstances, your system – the pipes, fittings, tanks, pumps, and other equipment – operates at or around a certain PSI. At this point, the pressure relief valve is not engaged and remains closed. Inside the relief valve there is a large, adjustable spring that is set to a specific pressure higher than that of the fluids in the system. When the pressure in the system is greater than that of the spring, it will force a small poppet inside to lift, compressing the spring, and opening the valve. Excess pressure is discharged, and PSI is reduced. Once it has returned to the desired operating pressure, the spring’s force will again be greater than that of the process fluid and will release, pushing the poppet back down into its seat, closing the valve, and returning the system to the appropriate pressure.

Specifications

Additional information

| Weight | 3 lbs |

|---|

You must be logged in to post a review.

Reviews